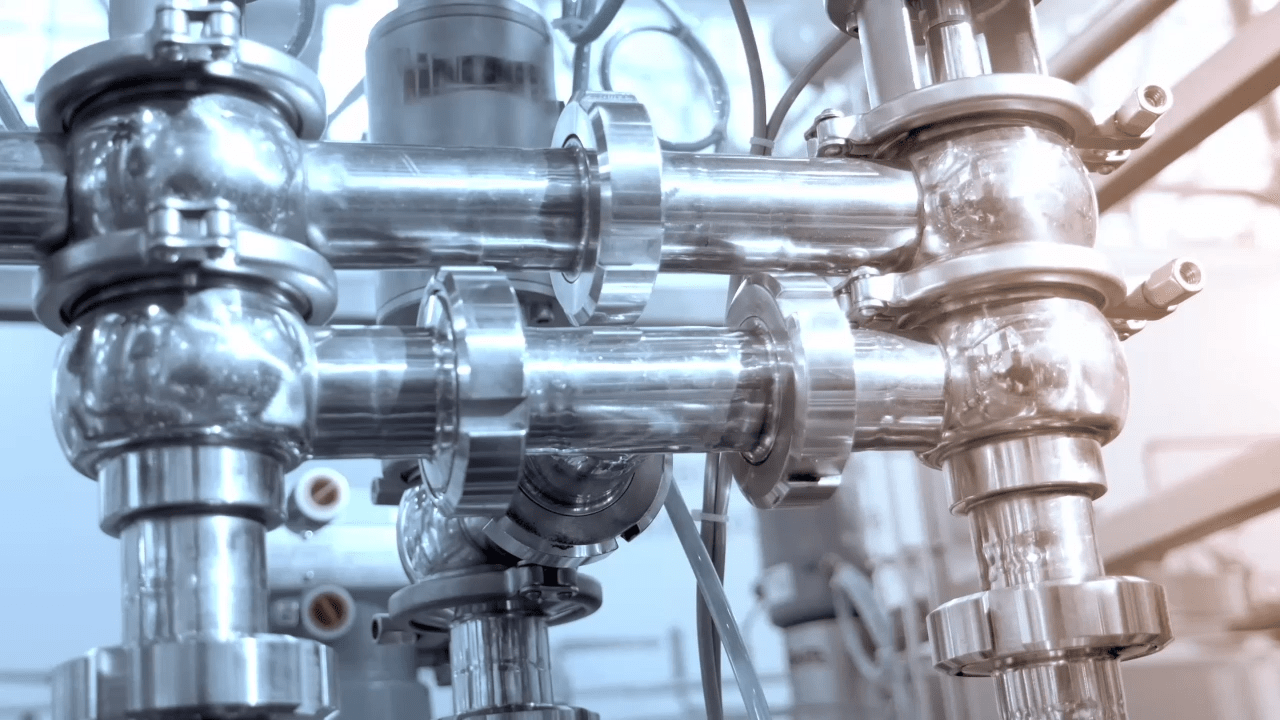

Maximising the Value of Existing Assets

There is an ever-increasing pressure to get the best out of existing plant and equipment. Modifications, upgrades and refurbishment can significantly improve process control, product consistency, and throughput without the cost and delay of complete equipment replacement and with significantly less impact to the business.

An Independent Alternative to OEMs

While original equipment manufacturers (OEMs) are often the first port of call for upgrades, Epsilon offers a qualified, impartial alternative. We bring deep industry experience and a vendor-neutral perspective, helping you make smarter decisions to improve operational efficiency at a significant cost reduction.

From Concept to Qualification

We manage the entire lifecycle of an equipment upgrade from initial specification, risk assessment and HAZOP, through to detailed design, stakeholder approval, execution, and final qualification. Our clients trust us to take full responsibility and deliver dependable results.

Minimising Downtime and Maximising Output

Taking equipment offline affects productivity, so we design every project to reduce downtime and deliver measurable impact fast. The frequency of repeat business we receive is a testament to our ability to meet these expectations under pressure.