A Smarter Approach to Used Equipment

At Epsilon, we offer a different perspective on used and redeployed pharmaceutical equipment. Our goal isn't just to resell—it’s to transform. We upgrade and refurbish used process equipment to meet today’s demanding cGMP, ATEX, CE, ASME/29CFR1910, and ISPE Baseline standards, bringing equipment up to par with European, American, and global regulatory requirements.

We provide full cGMP compliance at a fraction of the cost and in significantly shorter timeframes. This approach offers a genuine alternative to new equipment and introduces real competition into the market.

Reducing Risk, Delivering Confidence

With increasing consolidation in the pharmaceutical sector, high-quality equipment is frequently released back into the market. So why aren’t more companies considering used equipment? The short answer is risk. That’s where Epsilon comes in. We remove uncertainty by offering a complete supply solution that includes upgrading, validating, and customising the equipment to suit your exact needs. This ensures the process performs as expected and complies with all relevant standards.

Used equipment doesn’t have to mean compromise. We make sure it doesn’t.

Guidance from the Start

If you’re unsure whether used equipment is suitable for your project, we can assist early in the process. Our team provides high-level assessments on equipment condition and suitability to support your decision-making.

Why Consider Used and Upgraded Equipment?

- Very cost-effective, significantly less than new

- Equipment can be inspected and evaluated before purchase

- Shorter timelines from decision to operation

- A genuine alternative to new, with added value

Compliance Without Compromise

We eliminate contamination risks and return equipment to "as new" condition with full compliance. You can choose the control system that suits your needs, from basic interlocks and dials to full 21CFR Part 11 touchscreen HMI/SCADA packages with PID control. We walk you through the options and deliver a practical, cost-effective solution.

Plan with Confidence

Set your budget early and with confidence. Engage us to inspect the equipment and produce a detailed condition report. Together, we define what upgrades are required. We offer a full package, from inspections and costing to refurbishment, installation, qualification, manuals, and training—all included as part of our service.

Not Every Project Needs an Overhaul

Some equipment only requires minimal modification. We help you identify what’s truly needed so you don’t over-commit resources.

"Isn’t It Easier to Just Buy New?"

Traditionally, yes. Most used equipment suppliers focused on sales, not service. At Epsilon, we do things differently. We provide a complete solution, from assessment and upgrades to full operational handover. Our goal is not just to offer a lower-cost alternative, but a smarter, faster one. If we can’t deliver in less time than a new equipment order, we’ll tell you upfront.

Serious Competition for New

Today, more high-quality used pharmaceutical equipment is available than ever before. These assets present a serious cost-saving opportunity and can meet the same standards as new. Many original equipment manufacturers are focused on selling new units and are not interested in supporting upgrades. Epsilon fills that gap by offering customised upgrades that meet your process and compliance requirements.

Flexible, Tailored, Sustainable

We do not push inventory—we deliver what you need. Reusing and upgrading existing equipment also contributes to your corporate environmental goals by reducing waste and conserving energy and materials. Used equipment can be a sustainable and responsible choice without compromising on performance or compliance.

A Real Alternative to New Equipment

Used and upgraded equipment can now form the basis of a solid business case. It can meet expectations for cGMP compliance, performance, and long-term durability. If it’s right for your project, we will help you prove it.

Built on Experience

Will it really work once installed? What is the equipment going to do, and how does it fit into your process? Are you introducing a new product? With over 750 successful projects delivered, we know how to ask the right questions from the start. We provide an independent and honest view of whether the equipment you are considering is suitable. Our full package includes design qualification, factory acceptance testing, and in most cases, process guarantees. Our goal is to remove risk and increase confidence in your investment.

Contamination Risks, Managed

Contamination is a valid concern. We provide pharmaceutical-grade decontamination services through specialist partners. National laboratories perform inspections and testing using validated protocols, methodologies, and acceptance criteria. If the risk cannot be eliminated, we will let you know. Where necessary, we can subject equipment to dry vapour hydrogen peroxide (DVHP) decontamination for added assurance.

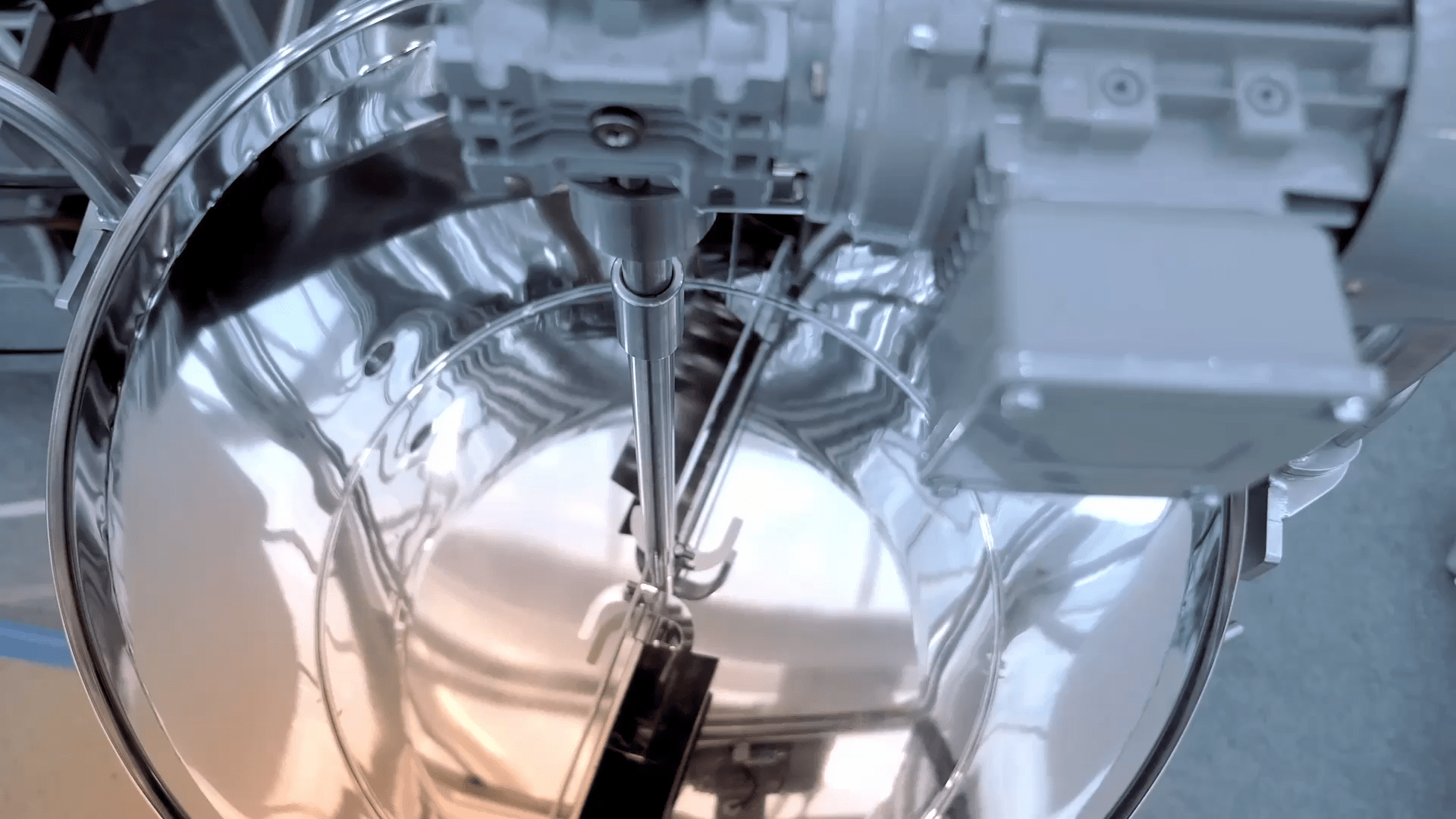

Polishing and Material Certification

We can repolish stainless steel product contact surfaces and provide certification for material composition (via x-ray) and surface finish. Passivation and electro-polishing are also available. As standard, we replace all product contact seals and gaskets to ensure quality and compliance from the start. Nothing is left to chance.